Thermal and Cracking Assessment

As concrete hydrates there is an exothermic reaction and the insitu temperature rise can cause a range of problems. It is vital that specifiers and contractors fully appreciate their roles in preventing damage. BCRC can assist both through correct design, specification and management of construction.

BCRC are leaders in the highly complex area of early age crack analysis of concrete structures. BCRC’s Managing Consultant in this area is Frank Papworth who has published various papers on practical implementation of CIRIA C660, the latest industry standard on analysis for crack width control. In 2008 BCRC consultants P.Bamforth (author of C660), Frank Papworth and Bob Munn ran a course on use of CIRIA C660.

In 2010 Mr Papworth chaired the Perth session of CIA’s 1 day workshop on cracking and a copy of his paper dealing with the crack width design process and construction issues is available from BCRC offices. Mr Papworth was also co-author of the Concrete Institute of Australia’s Durability Series Recommended Practice Z7-06 Concrete Cracking and Crack Control published in 2017, which complements CIRIA C660 by detailing more rigorous procedures for early age crack width modelling due to end and edge restraint for drying shrinkage. CIRIA C660 remains the seminal guidance document for thermal modelling and crack control reinforcement design, although various updates in published papers, recognition of the different procedures for thermal and shrinkage strains, and the influence of local materials properties must be accounted for.

BCRC has been involved on many major projects to undertake thermal and crack control analysis. BCRC’s service outline “Thermal analysis and crack control” details our design services. This section details the services BCRC provide for:

- Measurement of the heat generating capacity of the concrete (adiabatic and ‘hot box’ tests)

- Predicting the insitu temperature of a concrete pour and possible damage that may result

- Advice on modification to the proposed pour regime to avoid damage

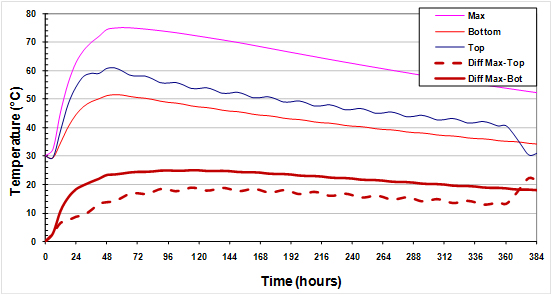

- Instrument full scale pours to confirm predicted results

BCRC’s senior consultants undertake analysis work while engineers and technicians are used for the instrumentation and provision of temperature test certificates. BCRC also provide a service for assessment of insitu strength using maturity.

Contractor Solutions

Contractors need to understand the risks from heat of hydration. BCRC can advise on management of the following problems:

- Maximum temperature exceeding acceptable limits

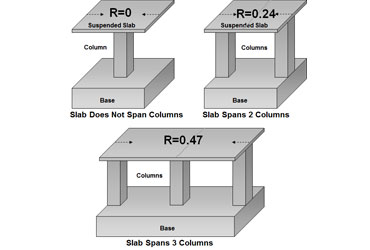

- The temperature differential between the centre of the pour and the concrete surface being so high that internal cracks occur

- The temperature differentials between a new pour and an adjacent pour leading to edge restraint cracks that are too wide

- Thermal contraction when a pour is restrained at its ends. End restraint cracks can be particularly wide as they are not distributed

On some projects thermal limits are included in the specification. These limits are frequently based on previous specification and may be unnecessarily onerous or may not be adequate to prevent damage occurring. BCRC can review projects and give contractors advice on where relaxation of specifications would be appropriate and/or how to most economically achieve the specified requirements.

Designs and specifications will not always control cracking adequately and this can lead to expensive repair requirements, particularly where elements are below water level. BCRC can undertake reviews of restrained elements to advise on whether design is adequate. We can also advise on whether the Contractor was responsible for cracks or whether the cracks stem from design and specification limitations.

On the more positive side BCRC can also help contractors use the heat of hydration. Concrete cures more rapidly at higher temperatures. Maturity measurement can be used to give much earlier stripping and stressing times. BCRC can help develop a maturity assessment programme.

Design Solutions

Early age crack analysis is a difficult issue for designers. Australian Codes provide limits on reinforcement stresses that are intended to provide adequate crack control. Unfortunately these limits are only suitable for ‘normal’ pours. The high heat of hydration of modern cement and high performance concretes, high restraint situations and high ambient temperatures can all lead to situations where the code steel stress limits will not be adequate and designers need to specifically assess crack widths and then specify practical limits on construction which will ensure the reinforcement is adequate to control cracking. BCRC provide the following specialist services for designers related to heat of hydration of concrete:

- Detailed analysis of insitu temperature rise by

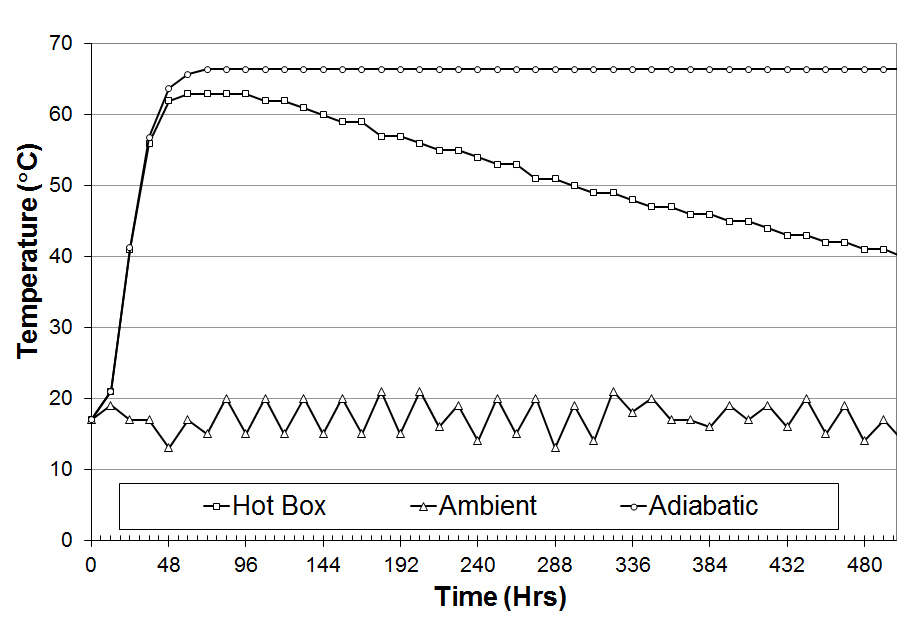

- measuring temperature rise in a hot box test during trial mixes

- calculation of the adiabatic temperature rise

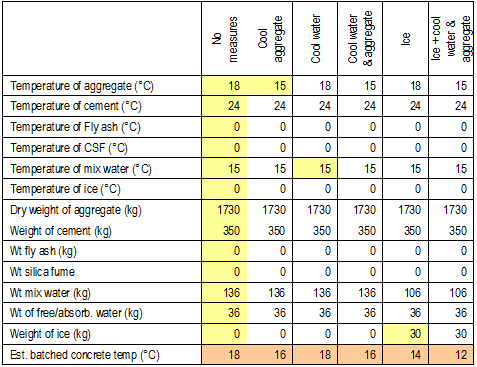

- calculation of insitu temperatures based on adiabatic temperature rise, pour thickness, ambient temperatures, concrete delivered temperatures and curing

- Assessment of restraint cracking based on CIRIA C660 methods and Bamforth/Papworth subsequent publications

- Detailing of reinforcement requirements for crack control

- Specification of construction requirements based on thermal anlaysis

Projects

- Newcastle to Ballina Pacific Highway Upgrades (Various)

- Jervois Bay wharf decks

- Wellington Street station foundation

- Mt Henry bridge pile caps and piers

- Ravensthorpe mine foundations up to 5.5m thick

- Paraburdoo rail foundations

- Thornlie rail bridge pile cap

- CSBP NAAN 3 thick foundations for chemical plant

- North west coastal highway rail bridge.